The latest development from THALMANN is the long folding TD200 bench; a smooth, fast and quiet double-folding machine, which takes up little space and is highly automated.

Thalmann news!

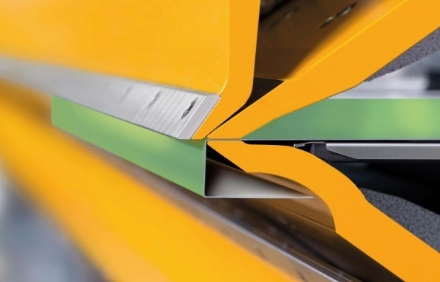

Thalmann has been pioneering the development and production of long-folding benches since 1960. The latest development is the Thalmann TD200 – a smooth, fast and quiet double bending machine, which takes up little space and offers a lot of automation for bending profile frames! This machine is based on Thalmann’s unique kinetic steering technology, with a high level of performance and synchronous power distribution along the entire length of the machine.

The exclusive dynamic folding technology (DFT) guarantees faster and smoother folding processes – without loss of precision.

THALMANN TD200 3.2 / TD150 4.0 – Faster and smoother

Why choose a TD200 3.2 or TD150 4.0?

- Fast and quiet, little space required

- Narrow folding blade for tight Z-bends, 10 mm with 10 mm carrier blade

- 35-degree top bar for more free space

- Curved lower beam for deep J channels or F/J channels

- 14 ga capacity – fantastic zoom

- 1250 mm back gauge, instead of 750 mm

- 700 mm blade extender instead of 500 mm

- Tapered bending/setting of profiles

- Automation can be added to the machine: side loader, profile-turn-flipper, unloading system

More Thalmann solutions

TZ Long folder – Innovative and efficient

The TZ long folder offers VFD design, steering technology, newly designed clamping and offset beams, dynamic crowning system and the brand new longitudinal cutter.

- VFD (Vertical Force Drive) design principle

- Synchronized torsion shafts

- Increased bending accuracy and additional free bending space

- Higher bending speeds and greater flexibility

- Better product quality and lower cost per bent part

- Maximum machine stability and service life due to stiffened side frame

TD Double bender – Fast and flexible

The TD double-bender offers tool and offset beam geometry, kinetic steering axis and remote maintenance using TeamViewer software.

- Automation solutions and individual additional functions

- Increased productivity and increased capacity

- Integration of digital solutions and open software interfaces of bending sequences

- Optimized bending freedom and maximum flexibility of colored sides, so no errors in the process

TC Double bender – Big and powerful

The TC double bender, or “Big Mama,” is designed with VFD principle, offset bending beam geometry, fully automatic gripper system, DFT drive and multi-zone bending beam crowning.

- Increased bending accuracy and additional free bending space

- Higher throughput and greater capacity

- Higher bending speeds and greater flexibility

- Minimal maintenance requirements and long service life