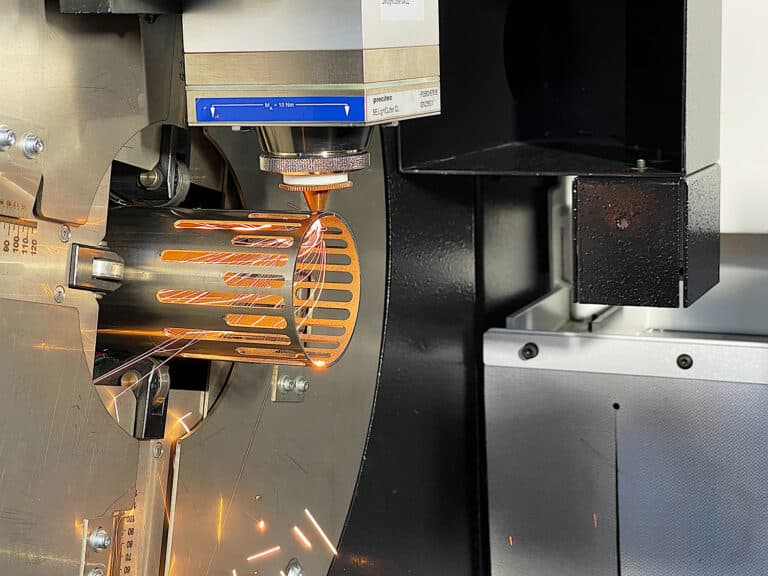

Tube laser cutting machine TF120 2D

with CM-L magazine loader

The TF120 is an advanced laser system for fast and accurate cutting of metal tubes of various sizes and thicknesses. With the latest generation of fiber laser technology and integrated software, it offers high productivity and maximum cutting quality. The machine processes pipes from Ø10 mm to Ø120 mm and is completely designed and built in Italy.

Key features

- Cutting straight, making holes and slots, marking and engraving

- Tongue and groove joints on round, square and rectangular tubes

- Materials: carbon steel, stainless steel, aluminum alloys and highly reflective materials

- All programming phases are managed through Almacam Tube CAD-CAM software

- Compact, safe, fast and fully automatic machine with intuitive interface

- Advanced tracking and control system for constant distance from the tube, even with complex shapes

CM-L magazine loader

- Fully automatic handling of round, square and rectangular tubes up to Ø120 mm

- Automatic adjustment when changing tube size

- Load bundles directly into basket, automatic roller unloading

- Load capacity: up to 4,000 kg, maximum length 6,050 mm (optional 12 m)

Key components and systems

These components are integrated into the machine:

- Brands: Balluff, Datasensor, Datalogic, ESA Automotion, Siemens/Schneider Electric, Shimpo, Motovario, Metalwork, Diwal, Precitec, IPG/N’Light, SMC, Sideros

- Control panel: 21.5″ touchscreen with 8GB RAM, optional 23″ display

Laser head and source

- Fiber laser source 2 kW (IPG)

- PRECITEC cutting head with autofocus and anti-collision sensor

- Suitable for cutting gases: nitrogen and oxygen

- Dual circuit cooling system for source and head

Fully automatic functions

- Mobile spindle (master) with 360° rotation for precise pipe movement

- Fixed spindle (slave) for stabilization

- Automatic clamp adjustment for different pipe diameters

- Fully automated tube followers and measurement switch

Support and disposal

- Multi-position discharge system up to 3,500 mm, suitable for short/long pieces and scrap metal

- Fine dust and smoke extraction with SIDEROS system, including filters and collection bins

- Dual circuit cooling system for constant cooling temperatures

Software and programming

- ALMA TUBE software for 3D CAD/CAM operations on tubes

- Libraries with tube sections, holes, macro parameters

- Automatic nesting function with material use optimization

- NC software with Windows XP Embedded interface, real-time G-code interpreter, remote control and network connection

- Interactive and automatic trajectory creation with collision detection and simulation

Machine capacity TF120 2D

| Feature | Specification |

|---|---|

| Cutting head | Precitec 2D |

| Total consumption power | 16 kW |

| Capacity round tube | Ø10 – Ø120 mm |

| Capacity square tube | 10×10 – 100×100 mm |

| Capacity rectangular tube | 10×20 – Ø120 inscribed |

| Cutting speed | 150 – 35,000 mm/min |

| Position speed X/Y | 100,000 mm/min |

| Acceleration | 9,800 mm/sec² |

| Charger | CM-L |

Cut thicknesses at IPG source:

- Carbon steel: 0.8 – 15 mm (depending on kW)

- Stainless steel: 0.8 – 8 mm

- Aluminum: 1 – 8 mm (optional)

- Brass: 0.8 – 6 mm (optional)

- Copper: 0.8 – 3 mm (optional)

Maintenance and support

- Annual or semi-annual routine maintenance

- Inspection, lubrication, cleaning, calibration, software updates

- Quick response times to breakdowns due to well-stocked spare parts inventory

- Remote assistance available via the Internet

Additional options

- Turnkey system: complete installation, supervision and training of operators

- Industry 4.0 Ready: ready for automated and connected manufacturing

- Microdoser for inerting powder (for aluminum)

- Chain-discharge table, welding reader, scrap conveyor, remote camera and cutting with compressed air

Tube laser TF120 2D

from € 500.000,-

| Lease options: | Op aanvraag |

The TF120 2D tube laser is an advanced laser system for fast and accurate cutting of metal tubes of various sizes and thicknesses.

About O.M.P. srl

Based in Santorso (Vicenza, Italy), O.M.P. has been designing and manufacturing advanced machinery and systems for tube and metalworking since 1977. With an 8,000 m² factory and an experienced team of 25+ employees, O.M.P. delivers technology that is robust, precise and reliable, with an international network in more than 40 countries.

Products:

- Tube Lasers

- Automatic disc saw lines

- Multi-head installations

- Bundling machines

- Deburring lines

- Bevel lines

- Rotary lines

- Handle lines

- Custom mechanical solutions

Testing, training and documentation

Opportunity for additional training at OMP or at customer site

Test at OMP in the presence of customer technicians

Training for 3-4 operators, 5 days, including use of machine and CAD/CAM programming

Documentation in Italian (other languages on request), including manuals, diagrams and spare parts lists

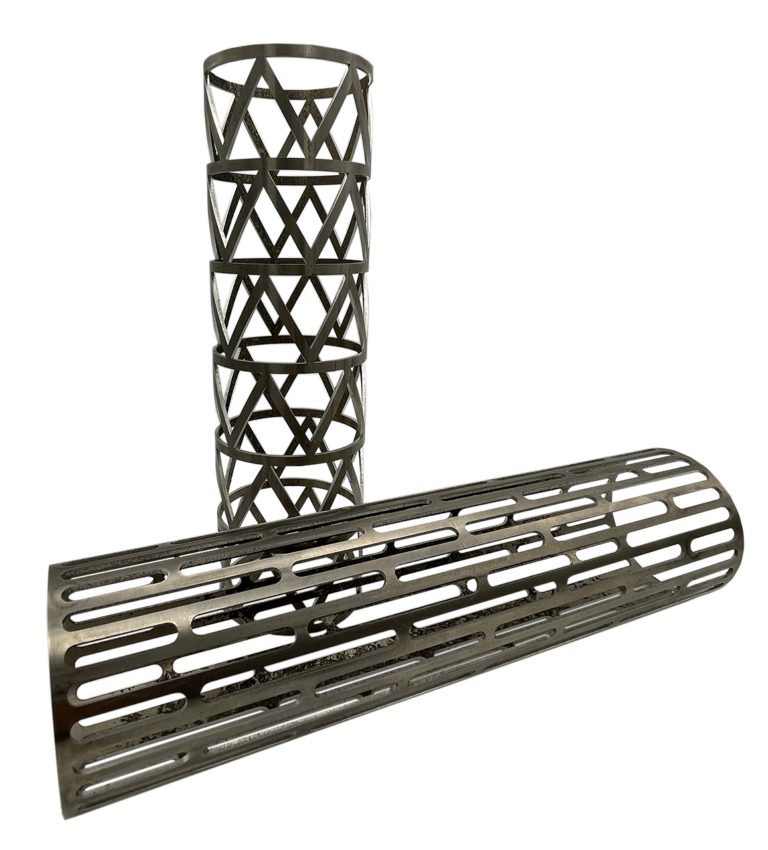

Samples

.

| TF120 2D technical information | |

| Max tube weight | 16 Kg / Meter |

| Charging – discharging | |

| Charger | Bundle tubes – sliding tubes |

| Minimum and maximum loadable length mm | Min 3,200 Max 6,050 (8,000 – 12,000 OPTION) |

| Discharge length mm | 3,000 (others upon request) |

| Laser | |

| Laser source | Fibra 1 – 3 KW (others upon request) |

| Cup type | Precitec 2D |

| General | |

| Precision mm | ± 0.1 / 200 |

| Workable materials | Steel | stainless steel | aluminum | copper | brass |

| Min/Max processing speed mm | 150/35.000 |

| X and Y axis positioning speed mm/min | 100.000 |

| Total consumption power | 16 KW |

| Machine dimensions mm | 14,267 x 3,572 x 2,138 |

| Machine weight | 9,600 kg |

Request a quotation

Interested in a (similar) machine, applications and/or possibilities? Contact us with no obligation!