The future of smart sheet metal processing:

The world of sheet metal working machines and roll forming machines is developing rapidly. Where once craftsmanship and manual work were the main focus, we now see a shift towards automated production lines, smart software and machines that respond flexibly to the market. For companies in roof and facade construction, mechanical engineering and manufacturing, this means that investing in innovation is essential.

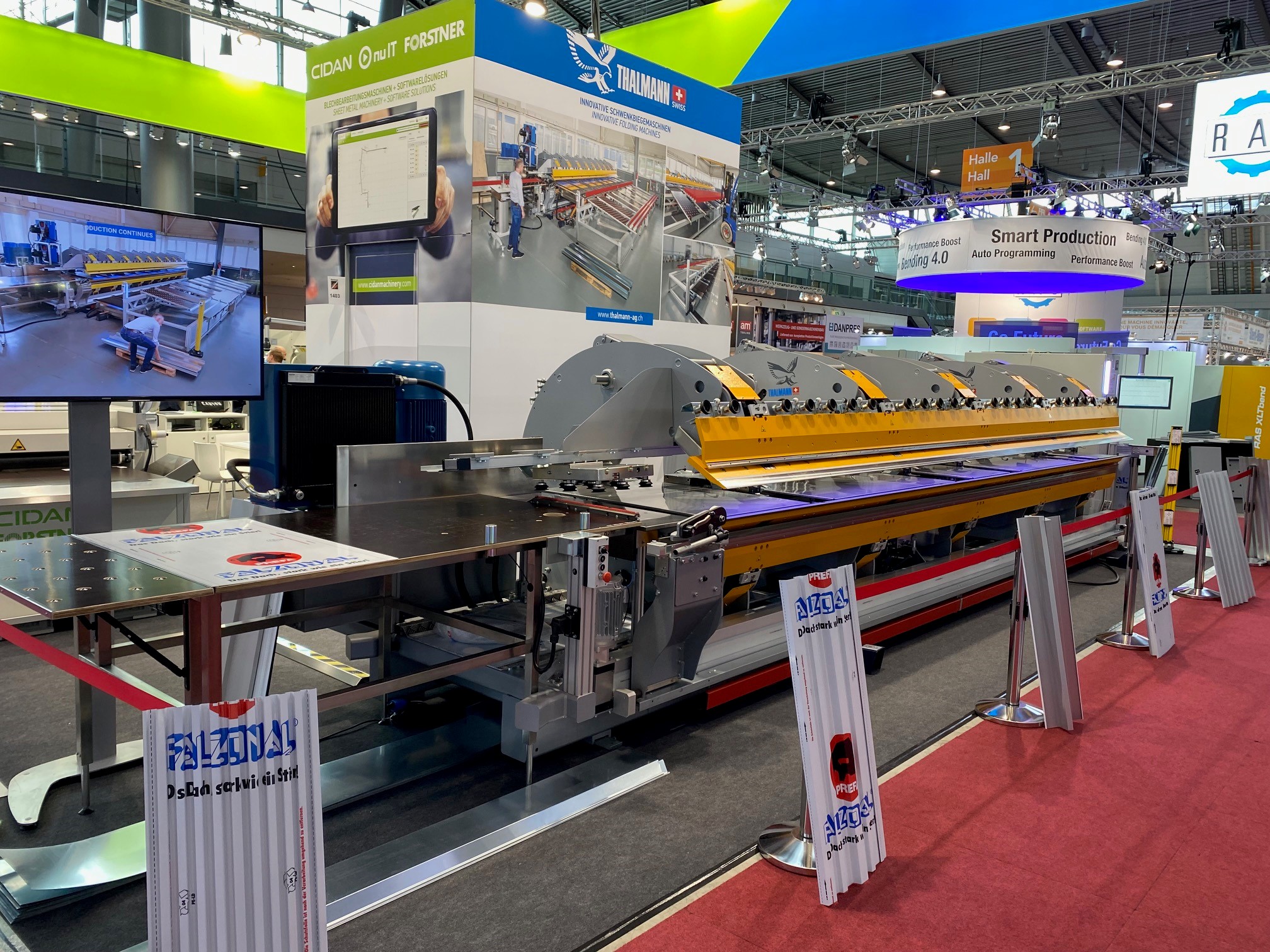

At Pasterkamp Metal Sheet Solutions, we follow these developments closely. As a supplier of leading brands such as CIDAN / Forstner / Thalmann, Coiltech, etc., we combine years of experience with the latest technologies in the field of coil processing and roll forming machines. In this blog we share five trends that define the future of sheet metal working – and that you can see live at BlechExpo 2025 in Stuttgart.

1. Automation and digitization of sheet metal working

Automation is now an integral part of the sheet metal working industry. Modern roll forming machines are equipped with software that allows you to easily monitor and control production lines. Settings are automatically adjusted based on material type, profile and product length, ensuring fewer errors and higher efficiency.

One example: with the latest roll forming lines an operator can load complete production runs and run the machine independently, saving time and costs.

2. Sustainability as standard

Sustainability is no longer a trend, but a requirement from customers and legislation. Manufacturers are developing energy-efficient sheet metal working machines and technologies that minimize material waste. The construction industry is also growing in demand for innovative products such as insulated roof and wall systems.

Investing in sustainable solutions not only saves energy and costs, but also strengthens your position in a competitive market.

3. Flexible production with roll forming machines

Customers increasingly expect customization and smaller production runs. Flexible roll forming machines and press brakes allow rapid switching between different profiles, lengths and materials.

Smart setup systems and automated processes allow you to respond faster to new market trends and provide customers with customized solutions.

4. Collaborate with strong brands

Delivering complete solutions requires strong partnerships. That is why Pasterkamp works together with brands such as CIDAN, Thalmann, Forstner and Coiltech. This allows us to provide companies with a complete package: from coil processing and slitting to roll forming machines and press brakes.

This collaboration ensures innovation and reliability at every stage of your production process.

5. Discovering innovations at BlechExpo 2025

The best way to see the latest technology in action is to visit BlechExpo 2025. From October 21 to 24, we will be in Hall 3, booth 3400.

Here we show you how smart sheet metal working machines and advanced roll forming machines can make your production smarter, faster and more efficient. It’s the perfect time to ask your questions and discuss solutions that will move your business forward.

Conclusion

The future of sheet metal working is all about innovation, sustainability and flexibility. By investing in modern technology and working with reliable partners, you can optimize your production process and prepare it for the future.

📅 Schedule an appointment now for BlechExpo 2025

Would you like a personal demonstration or advice on your production process? Please contact us at office@pasterkamp.nl or schedule an appointment at www.pasterkamp.nl.