In the world of sheet metal processing, efficiency is essential, especially when it comes to processing large quantities of thin sheet materials. More and more companies are discovering the advantages of a fully automated production line, where the process starts right from the coil and ends with a fully finished product. But what makes this way of working so attractive? And how can custom machines designed specifically for your needs make a real difference?

1. A seamless workflow: More control and less manual intervention

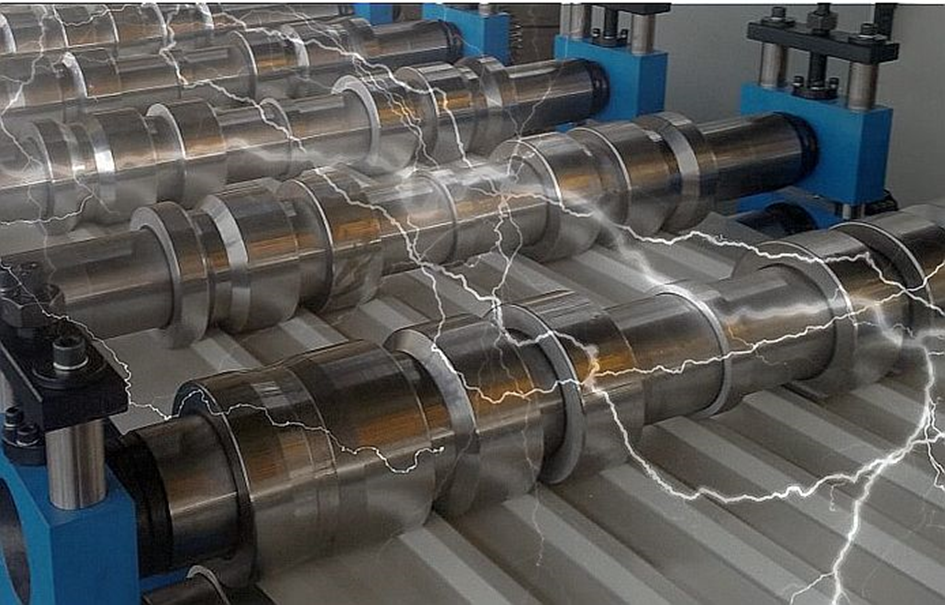

A traditional production line often requires a lot of manual intervention to properly align various processing steps. With an automated solution that works directly from the coil, these additional operations are largely eliminated. The coil is fed directly into the system, after which the material goes through a series of operations, such as cutting, forming, bending and punching. Because everything fits together seamlessly, the process remains fluid and runs without interruptions.

2. Time and cost efficiency: the most valuable benefits

An integrated solution not only speeds up production time but also saves costs. With fewer material losses, higher speeds and consistent quality, there are significant savings. In addition, maintenance and downtime are minimized. Consider cost savings from reduced waste and the lower energy requirements of an optimally tuned system.

3. Custom precision: The machine as an extension of your expertise

Whether complex profiles or special shapes are involved, automated machines are designed to meet desired specifications with great precision. With a custom machine, settings can be tailored precisely to your product requirements. This ensures that you can offer unique products that not only meet the highest standards, but are also perfectly tailored to the demand in your market.

4. Increased flexibility and scalability

The demand for sheet metal products often fluctuates. An automated system provides the flexibility to easily switch between production runs. Want to switch from a small run to mass production, or change a product design? With a well-designed custom system, this is no problem, without the need for lengthy conversions or modifications.

5. Customer-focused innovation: What makes our custom solutions unique

Our approach is not simply to sell you a machine; we deliver a solution designed specifically to meet your specific production needs. By working with our engineers, you can count on a system that will help you optimize your production processes and respond flexibly to new challenges in the future.

Conclusion: A profitable investment in automation – from coil to finished product

Moving to an automated sheet metal production line from coil is an investment that quickly pays off. Less manual intervention, faster production speeds, lower costs and accurate, customer-focused results make all the difference in a competitive marketplace. Our custom machines are designed with your success in mind – from coil to complete finished product.

Please feel free to get in touch!

Are you interested in what automation can do for your production process? Contact us for a no-obligation consultation and find out how we can transform your production line with our innovative customized solutions!