- CNC-controlled crowning of folding beam

- CNC folder that folds up and down, no need to flip the material.

- 150 mm movement of the folding beam, to move outside the material on the folding side.

- The Combibar is equipped with 203 mm high divided tools and a straight rail.

- Standard features include multiple tooling, CNC-controlled sheet thickness and bending center adjustment.

- The folding bar can be used as a front stop up to 150 mm.

- Add vacuum grippers to make work even lighter, more precise and automated!

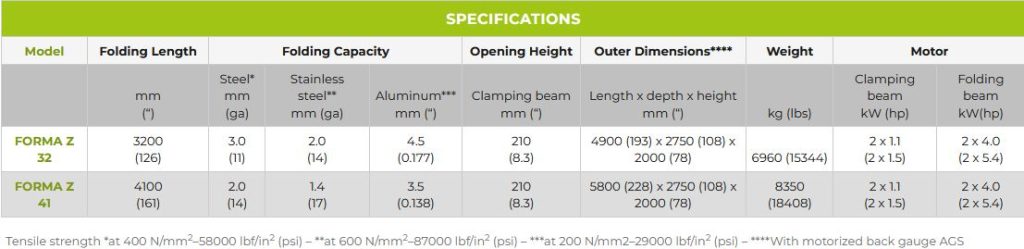

CIDAN Folding machine FORMA Z

from € 50.000,-

| Lease options: | € 1.003,- 60 months € 724,- 96 months |

CIDAN’s press brakes are available in different versions

NOW EVEN FASTER!

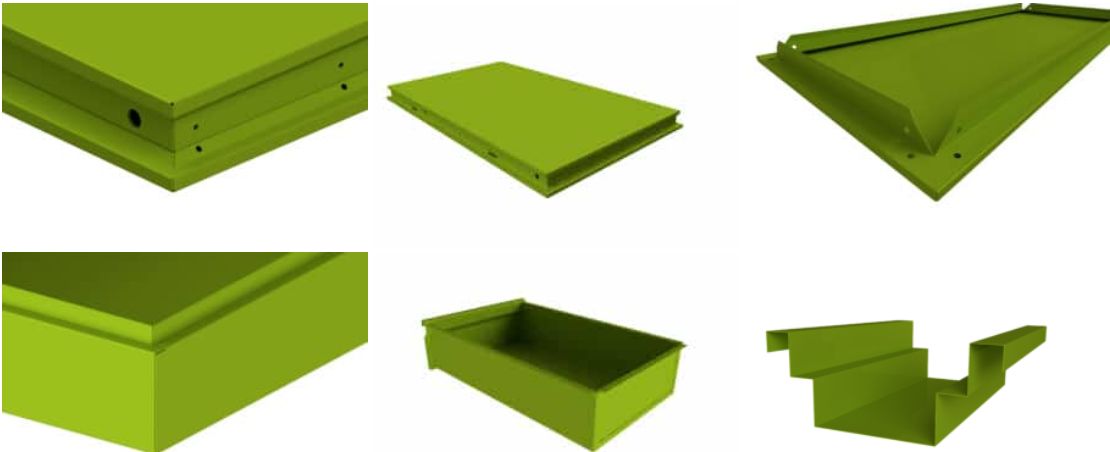

The FORMA Z folding machine is CIDAN’s most flexible and diverse sheet folding machine.

The FORMA Z-setting bench, can set both up and down, eliminating the need to reverse the material, allowing complex parts to be set time-efficiently by one operator. Combi beam rotation between two tool positions and unique geometry give you unparalleled workspace. The automatic tool lock is fast and makes changing tools very ergonomic.

The folding bar has automatic crowning, automatic adjustment of the setting center and automatic adjustment of the sheet thickness, which provides a superior folding quality provides superior setting quality in all thicknesses and over the setting length. The large number of vacuum grippers holds the part firmly, anywhere on the backgauge, large and small plates, both single and multiple.

The back gauge is available in many versions, giving you great freedom of choice in the direction of work and how you want to operate the machine.

Last but not least – FORMA Z is fast: so more production in less time!

Standard

- CNC-controlled crowning of folding beam

- CNC folder that folds up and down, no need to flip the material.

- Operating system ProLink W 21.5″ widescreen with integrated buttons

- CNC-controlled plate thickness and fold setting center

- Multifold: all three bars feature segmented tools

- The folding bar comes with segmented tools of 8 mm (.3″), 12 mm (.47″), 15 mm (.6″) or 25 mm (.98″)

- Floor scanner on folding beam side, light curtain on both set and stop side

- Back stop can be supplied with vacuum gripper; and/or with height adjustment – entirely as desired; minimum size is 6 mm for spring steel fingers (AGS)

- Automatic locking of high divided and folding beam tools

- Automatic lubrication

- Integrated tool storage compartment on the left side (viewed from the folding side).

Request a quotation

Interested in a (similar) machine, applications and/or possibilities? Contact us without any obligation!