Application

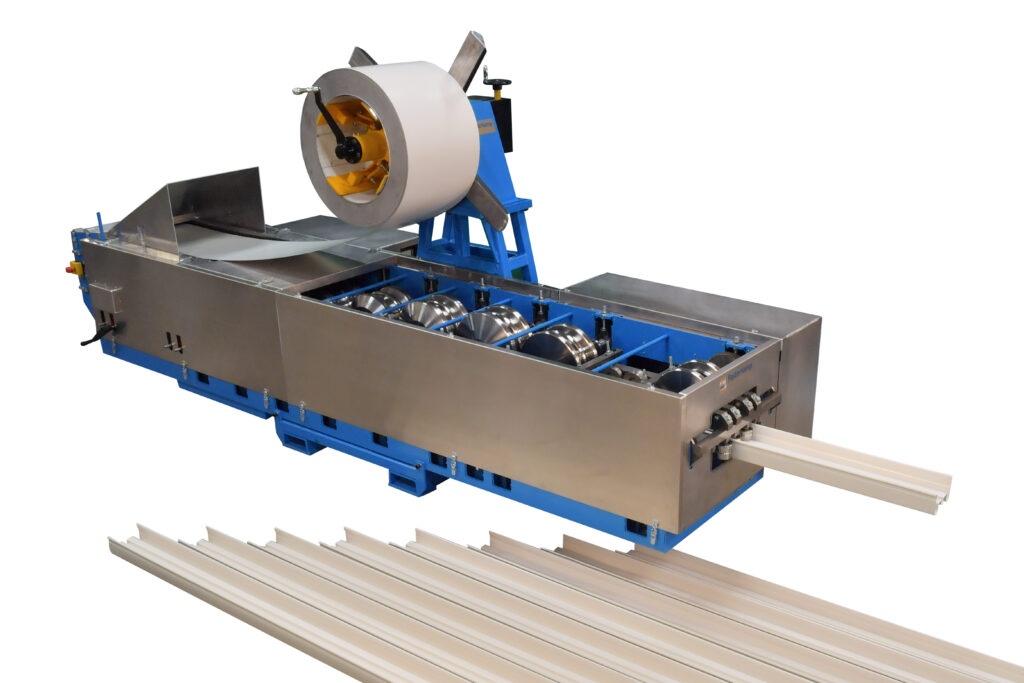

Mobile roll forming machines are designed for on-site roll forming of profiles from coil.

The coil hangs above or below the machine and the whole unit is movable to produce profiles in the right position or in a special place. Often these are longer lengths that are therefore impossible to transport.

Mobile roll forming machine for cultivation gutters

from € 137.500,-

| Lease options: | € 2.769,- 60 months € 1.931,- 96 months |

Materials

Different materials are produced on a mobile roll former. Material can have a width of 800 mm, or a narrower profile with a thickness of 3 mm. Coated or galvanized material but also Magnelis is used.

Specifications

Being mobile with these machines can be done in several ways:

- Machines are mounted on a trailer so the machine can be on site quickly and start production immediately.

- Machines have also been made suitable for moving the machine using a telescopic handler. We see this especially in horticulture where in the middle of the field very long cultivation gutters are produced of up to 200 meters long.

- The most commonly used option is the version with powered tracks. The machine is then self-propelled and can therefore maneuver freely on site.

- Furthermore, for application in the solar industry, machines have been mounted in containers. In this process, the profiles used for a field of solar panels are manufactured and assembled on site.

Rotary punching equipment is also mounted on several mobile machines so that drainage holes are punched at even intervals.

Features

The specialty of making a mobile machine is mainly the limitation in length. Roll forming often requires a lot of length to form a profile step by step. This is especially true as the material becomes thicker and the profile higher. So at each step it is manually calculated whether it can be done and whether it does not give distortions that are not desired.

Request a quotation

Interested in a (similar) machine, applications and/or possibilities? Contact us without any obligation!