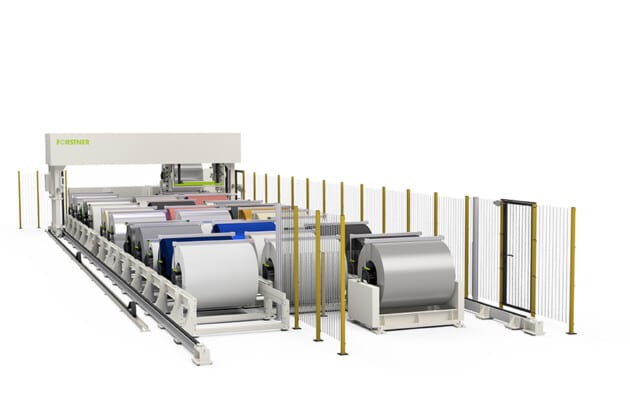

Decoiler and feeder

Coil handling with an unwinding reel or decoiler/uncoiler is possible with a mandrel that can change in diameter. This allows the coil to be securely clamped and to remain firmly positioned on the shaft during operation.

A decoiler is available in various configurations: manually operated or electrically driven, with single or double mandrel execution, with or without a coil car, and in a wide range of sizes and capacities.

Material feeding is an essential part of the decoiling process. The infeed system ensures controlled and continuous feeding of the strip from the decoiler into the downstream equipment, such as straighteners, roll forming lines, or cutting units. Depending on the application, the feeder may consist of pinch rolls, guide tables, centering devices, and loop control systems to maintain constant strip tension and stable line speed. Proper infeed design contributes to accurate positioning, smooth operation, and reliable production performance.